麦王产品

Product

Release Time:2018-06-07

View Count:4336

McWong is pleased to present this proposal for a tank cleaning system for floating roof crude oil storage tanks. This system represents the latest cleaning technology that is used around the world for cleaning large, floating roof, oil storage tanks.

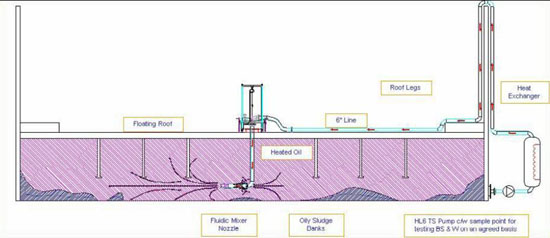

Tank cleaning schematics:

This system includes some of the latest sludge treatment techniques developed by Willacy Oil Services as well as proprietary equipment sold only by McWong.

The system provided will meet the following specifications:

Treatment Capability:

• Tank Cleaning of floating roof crude oil storage tanks with a maximum diameter of 80m. (Larger tanks can be cleaned using this system, however it would require the purchase of additional fluidic nozzles.)

After Tank Cleaning:

· Waxy sludge banks will be melted away!

· 95% of all oil contained in the sludge will be re-blended back into the crude oil for treatment at the refinery!

· Solids will be dewatered and ready for disposal at a landfill!

· Man – Entry will be significantly safer after water washing!

Mobile system:

· The system will be provided on multiple skids so that the system can be easily moved from tank to tank.

Sludge Profiling For Oil Tanks - SPOT Systemand

Our SPOT system uses a unique Tradebe patented sonar technology to profile sludge banks in crude oil tanks to a very high level of accuracy. During a 360º sweep, 240,000 soundings are taken to assess the sludge build up. The equipment is ATEX compliant and comprises:

• The sonar arm - requires a small diameter entry point from tank roof

• Proprietary software

•The SPOT system locates and quantifies sludge banks in oil tanks. The measurement accuracy is typically 99% with a rapid survey time. The results are presented in a report in 2 and 3 dimensions. The SPOT system has many advantages over manual dipping methods including safety, accuracy, practicality and cost.

Tank cleaning equipment—— Fluidic nozzles system

Fluidic nozzles are large eductor jets that are specially designed to operate in an oil tank. The systems mount on the roof of a floating tank and can be installed with the floating roof in any position. This allows for the tank to remain in service for the longest possible time. (Other technologies require that the floating roof be landed before the insertion of the cleaning nozzles, which means that the tank is out of service long before the cleaning actually begins.) The nozzles are designed with a maximum flow rate of 300m3/hr and the spray action from the nozzles has an effective radius of 40 meters from the nozzle. Fluidic nozzles constantly rotate (about 3-4 revolutions per hour) so even just one nozzle can have an immense effect on a tank. The fluidic nozzle system can operate submerged in the oil. There is no need for a Nitrogen layer.

Features of Fluidic nozzles system:

• The fluidic nozzle system can operate at any level while the floating roof is still floating;

• The system can be installed while the tank is still in service;

• Very few nozzles are used;

• The fluidic nozzle system uses a larger amount of oil while cleaning the tank.

Specialised Equipment / System

• Hydrodozer

The Hydrodozer is used to remove sludge from the bottom of the tank once the side manways are open. The Hydrodozer can be broken down into component form, reassembled inside the tank and operated remotely from outside the manway. This system allows for an increase in productivity and reduces man presence inside the tank. The Hydrodozer is hydraulically powered and is ATEX compliant.

Floating Barges:

To facilitate the extraction of sludge from the bottom of pits and lagoons with clay or impervious liners whilst the lagoon/pit is kept in operation. The floating barges are managed through steel wires and powered through hydraulic motors. The units have pumps and suction devices that can be regulated in height.

Hydrodreger:

This allows for the extraction of sludge while lagoon or pit is kept in service by using a remotely operated submersible robot fitted with a pump. This is hydraulically powered and different combinations are possible depending on the task.